What Components and Modules Does the Button Battery Holder Contain?

I. Introduction

Button battery holders are essential components in the world of electronics, providing a secure and reliable means of connecting small, round batteries—commonly known as button or coin cells—to various devices. These holders not only facilitate the easy replacement of batteries but also ensure that the electrical connection is stable and efficient. In this article, we will delve into the various components and modules that make up button battery holders, exploring their functions, materials, and significance in electronic applications.

II. Understanding Button Batteries

A. Description of Button Batteries

Button batteries, also referred to as coin cells, are small, cylindrical batteries that are widely used in a variety of electronic devices. They come in different sizes and chemistries, with some of the most common types being CR2032 and LR44.

1. **Types of Button Batteries**:

- **CR2032**: A lithium coin cell battery, typically used in watches, calculators, and motherboards.

- **LR44**: An alkaline button cell battery, often found in toys, medical devices, and small electronics.

2. **Common Applications**: Button batteries are prevalent in consumer electronics, medical devices, and even industrial applications, powering everything from wristwatches to remote controls and hearing aids.

B. Importance of Battery Holders in Ensuring Functionality

Battery holders play a crucial role in ensuring that button batteries function effectively. They provide a secure fit, maintain electrical contact, and allow for easy battery replacement, which is vital for devices that require frequent battery changes.

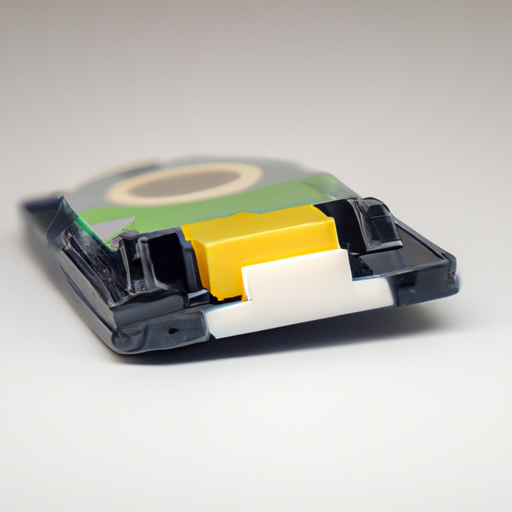

III. Components of a Button Battery Holder

A. Housing

The housing of a button battery holder is the outer shell that encases the battery and its components.

1. **Material Composition**:

- Typically made from plastic or metal, the choice of material affects durability, weight, and cost.

- Plastic housings are lightweight and cost-effective, while metal housings offer enhanced durability and conductivity.

2. **Design Considerations**:

- The size and shape of the housing must accommodate the specific type of button battery it is designed for, ensuring a snug fit.

B. Contacts

Contacts are the conductive elements that connect the battery to the device's circuit.

1. **Positive and Negative Terminals**:

- Each button battery holder has designated positive and negative terminals that correspond to the battery's terminals, ensuring correct polarity.

2. **Conductivity and Material Choices**:

- Common materials for contacts include copper and nickel, chosen for their excellent conductivity and resistance to corrosion.

C. Spring Mechanism

The spring mechanism is a vital component that secures the battery in place.

1. **Functionality in Securing the Battery**:

- The spring exerts pressure on the battery, ensuring a tight fit and maintaining contact with the terminals.

2. **Types of Springs Used**:

- Compression springs are commonly used in button battery holders, providing the necessary force to keep the battery securely in place.

D. Retaining Clip or Cover

The retaining clip or cover serves to hold the battery securely within the holder.

1. **Purpose in Battery Retention**:

- It prevents the battery from falling out during use or transport, ensuring reliable operation.

2. **Variations in Design**:

- Designs can vary from snap-fit mechanisms to screw-on covers, depending on the application and required security level.

E. Insulation

Insulation is crucial for preventing short circuits and ensuring safe operation.

1. **Importance of Preventing Short Circuits**:

- Proper insulation protects against accidental contact between the battery terminals and other conductive materials.

2. **Materials Used for Insulation**:

- Common insulation materials include rubber and plastic, chosen for their electrical insulating properties.

IV. Modules Associated with Button Battery Holders

A. Circuit Integration

Button battery holders are designed to integrate seamlessly with electronic circuits.

1. **How Battery Holders Connect to Electronic Circuits**:

- The contacts of the holder connect directly to the circuit board, allowing for the flow of electricity.

2. **Importance of Proper Alignment and Contact**:

- Ensuring that the battery holder is correctly aligned with the circuit is crucial for optimal performance.

B. LED Indicators

Some button battery holders come equipped with LED indicators.

1. **Use of LED Indicators in Battery Holders**:

- These indicators provide visual feedback on the battery's status, such as whether it is connected or needs replacement.

2. **Functionality and Benefits**:

- LED indicators enhance user experience by providing immediate information about battery health.

C. Voltage Regulation Modules

Voltage regulation modules are essential for maintaining consistent voltage output.

1. **Role in Maintaining Consistent Voltage Output**:

- These modules ensure that the device receives a stable voltage, regardless of battery charge levels.

2. **Types of Voltage Regulators Used**:

- Common types include linear regulators and switching regulators, each with its advantages depending on the application.

D. Safety Features

Safety features are critical in preventing battery-related hazards.

1. **Fuses and Circuit Breakers**:

- These components protect against overcurrent situations, preventing damage to the device and battery.

2. **Over-Discharge Protection Mechanisms**:

- Some battery holders include mechanisms to prevent the battery from discharging too much, which can extend battery life and prevent leakage.

V. Manufacturing Considerations

A. Production Processes for Button Battery Holders

The manufacturing of button battery holders involves several processes.

1. **Injection Molding for Plastic Components**:

- This process allows for the mass production of plastic housings with precise dimensions.

2. **Metal Stamping for Contacts**:

- Metal stamping is used to create the contacts, ensuring they are uniform and conductive.

B. Quality Control Measures

Quality control is essential to ensure the reliability of battery holders.

1. **Testing for Conductivity and Durability**:

- Manufacturers conduct tests to ensure that the contacts provide reliable conductivity and that the housing can withstand wear and tear.

2. **Compliance with Safety Standards**:

- Adhering to industry safety standards is crucial for ensuring that battery holders are safe for consumer use.

VI. Applications of Button Battery Holders

A. Consumer Electronics

Button battery holders are widely used in consumer electronics.

1. **Watches, Remote Controls, and Toys**:

- These devices often rely on button batteries for their compact size and long-lasting power.

B. Medical Devices

In the medical field, button battery holders are critical.

1. **Hearing Aids and Glucose Monitors**:

- These devices require reliable power sources, making button battery holders indispensable.

C. Industrial Applications

Button battery holders also find applications in industrial settings.

1. **Sensors and Monitoring Devices**:

- Many industrial sensors use button batteries for their compact size and reliability.

VII. Future Trends and Innovations

A. Advancements in Materials and Design

The future of button battery holders looks promising with advancements in materials and design.

B. Integration with Smart Technology

As technology evolves, button battery holders may integrate with smart devices, enhancing functionality.

C. Environmental Considerations and Recycling

With growing environmental concerns, the recycling of button batteries and holders is becoming increasingly important.

VIII. Conclusion

Button battery holders are vital components in a wide range of electronic devices, ensuring reliable power supply and ease of use. Understanding the various components and modules that make up these holders highlights their importance in modern technology. As we continue to innovate and improve upon existing designs, the future of button battery holders will likely see exciting advancements that enhance their functionality and sustainability.

IX. References

For further reading and resources on button battery holders and their applications, consider exploring industry standards and guidelines related to battery technology and safety.

What Components and Modules Does the Button Battery Holder Contain?

I. Introduction

Button battery holders are essential components in the world of electronics, providing a secure and reliable means of connecting small, round batteries—commonly known as button or coin cells—to various devices. These holders not only facilitate the easy replacement of batteries but also ensure that the electrical connection is stable and efficient. In this article, we will delve into the various components and modules that make up button battery holders, exploring their functions, materials, and significance in electronic applications.

II. Understanding Button Batteries

A. Description of Button Batteries

Button batteries, also referred to as coin cells, are small, cylindrical batteries that are widely used in a variety of electronic devices. They come in different sizes and chemistries, with some of the most common types being CR2032 and LR44.

1. **Types of Button Batteries**:

- **CR2032**: A lithium coin cell battery, typically used in watches, calculators, and motherboards.

- **LR44**: An alkaline button cell battery, often found in toys, medical devices, and small electronics.

2. **Common Applications**: Button batteries are prevalent in consumer electronics, medical devices, and even industrial applications, powering everything from wristwatches to remote controls and hearing aids.

B. Importance of Battery Holders in Ensuring Functionality

Battery holders play a crucial role in ensuring that button batteries function effectively. They provide a secure fit, maintain electrical contact, and allow for easy battery replacement, which is vital for devices that require frequent battery changes.

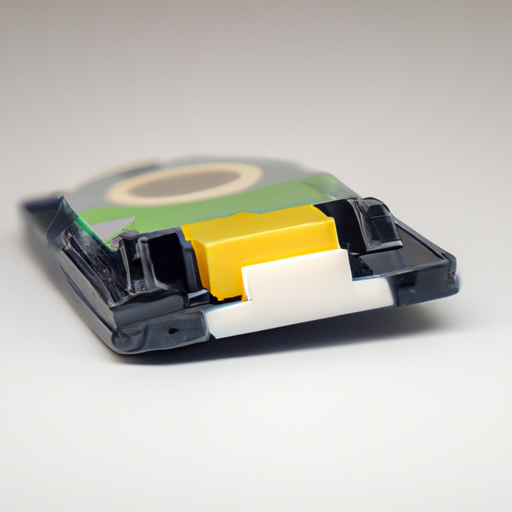

III. Components of a Button Battery Holder

A. Housing

The housing of a button battery holder is the outer shell that encases the battery and its components.

1. **Material Composition**:

- Typically made from plastic or metal, the choice of material affects durability, weight, and cost.

- Plastic housings are lightweight and cost-effective, while metal housings offer enhanced durability and conductivity.

2. **Design Considerations**:

- The size and shape of the housing must accommodate the specific type of button battery it is designed for, ensuring a snug fit.

B. Contacts

Contacts are the conductive elements that connect the battery to the device's circuit.

1. **Positive and Negative Terminals**:

- Each button battery holder has designated positive and negative terminals that correspond to the battery's terminals, ensuring correct polarity.

2. **Conductivity and Material Choices**:

- Common materials for contacts include copper and nickel, chosen for their excellent conductivity and resistance to corrosion.

C. Spring Mechanism

The spring mechanism is a vital component that secures the battery in place.

1. **Functionality in Securing the Battery**:

- The spring exerts pressure on the battery, ensuring a tight fit and maintaining contact with the terminals.

2. **Types of Springs Used**:

- Compression springs are commonly used in button battery holders, providing the necessary force to keep the battery securely in place.

D. Retaining Clip or Cover

The retaining clip or cover serves to hold the battery securely within the holder.

1. **Purpose in Battery Retention**:

- It prevents the battery from falling out during use or transport, ensuring reliable operation.

2. **Variations in Design**:

- Designs can vary from snap-fit mechanisms to screw-on covers, depending on the application and required security level.

E. Insulation

Insulation is crucial for preventing short circuits and ensuring safe operation.

1. **Importance of Preventing Short Circuits**:

- Proper insulation protects against accidental contact between the battery terminals and other conductive materials.

2. **Materials Used for Insulation**:

- Common insulation materials include rubber and plastic, chosen for their electrical insulating properties.

IV. Modules Associated with Button Battery Holders

A. Circuit Integration

Button battery holders are designed to integrate seamlessly with electronic circuits.

1. **How Battery Holders Connect to Electronic Circuits**:

- The contacts of the holder connect directly to the circuit board, allowing for the flow of electricity.

2. **Importance of Proper Alignment and Contact**:

- Ensuring that the battery holder is correctly aligned with the circuit is crucial for optimal performance.

B. LED Indicators

Some button battery holders come equipped with LED indicators.

1. **Use of LED Indicators in Battery Holders**:

- These indicators provide visual feedback on the battery's status, such as whether it is connected or needs replacement.

2. **Functionality and Benefits**:

- LED indicators enhance user experience by providing immediate information about battery health.

C. Voltage Regulation Modules

Voltage regulation modules are essential for maintaining consistent voltage output.

1. **Role in Maintaining Consistent Voltage Output**:

- These modules ensure that the device receives a stable voltage, regardless of battery charge levels.

2. **Types of Voltage Regulators Used**:

- Common types include linear regulators and switching regulators, each with its advantages depending on the application.

D. Safety Features

Safety features are critical in preventing battery-related hazards.

1. **Fuses and Circuit Breakers**:

- These components protect against overcurrent situations, preventing damage to the device and battery.

2. **Over-Discharge Protection Mechanisms**:

- Some battery holders include mechanisms to prevent the battery from discharging too much, which can extend battery life and prevent leakage.

V. Manufacturing Considerations

A. Production Processes for Button Battery Holders

The manufacturing of button battery holders involves several processes.

1. **Injection Molding for Plastic Components**:

- This process allows for the mass production of plastic housings with precise dimensions.

2. **Metal Stamping for Contacts**:

- Metal stamping is used to create the contacts, ensuring they are uniform and conductive.

B. Quality Control Measures

Quality control is essential to ensure the reliability of battery holders.

1. **Testing for Conductivity and Durability**:

- Manufacturers conduct tests to ensure that the contacts provide reliable conductivity and that the housing can withstand wear and tear.

2. **Compliance with Safety Standards**:

- Adhering to industry safety standards is crucial for ensuring that battery holders are safe for consumer use.

VI. Applications of Button Battery Holders

A. Consumer Electronics

Button battery holders are widely used in consumer electronics.

1. **Watches, Remote Controls, and Toys**:

- These devices often rely on button batteries for their compact size and long-lasting power.

B. Medical Devices

In the medical field, button battery holders are critical.

1. **Hearing Aids and Glucose Monitors**:

- These devices require reliable power sources, making button battery holders indispensable.

C. Industrial Applications

Button battery holders also find applications in industrial settings.

1. **Sensors and Monitoring Devices**:

- Many industrial sensors use button batteries for their compact size and reliability.

VII. Future Trends and Innovations

A. Advancements in Materials and Design

The future of button battery holders looks promising with advancements in materials and design.

B. Integration with Smart Technology

As technology evolves, button battery holders may integrate with smart devices, enhancing functionality.

C. Environmental Considerations and Recycling

With growing environmental concerns, the recycling of button batteries and holders is becoming increasingly important.

VIII. Conclusion

Button battery holders are vital components in a wide range of electronic devices, ensuring reliable power supply and ease of use. Understanding the various components and modules that make up these holders highlights their importance in modern technology. As we continue to innovate and improve upon existing designs, the future of button battery holders will likely see exciting advancements that enhance their functionality and sustainability.

IX. References

For further reading and resources on button battery holders and their applications, consider exploring industry standards and guidelines related to battery technology and safety.