What is the Main Application Direction of the Battery Holder Pin?

I. Introduction

In the realm of electronics, the battery holder pin plays a crucial role in ensuring that devices receive the power they need to function effectively. A battery holder pin is a small yet essential component that connects batteries to electronic circuits, allowing for the transfer of electrical energy. As technology continues to evolve, the importance of battery holder pins in various electronic devices cannot be overstated. This blog post will explore the main application directions of battery holder pins, highlighting their significance across different industries.

II. Understanding Battery Holder Pins

A. Description and Functionality

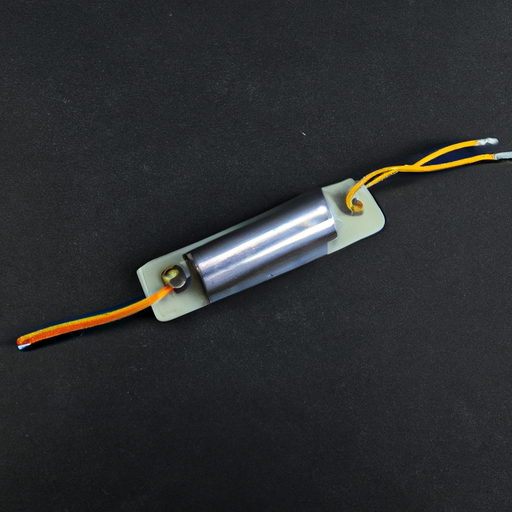

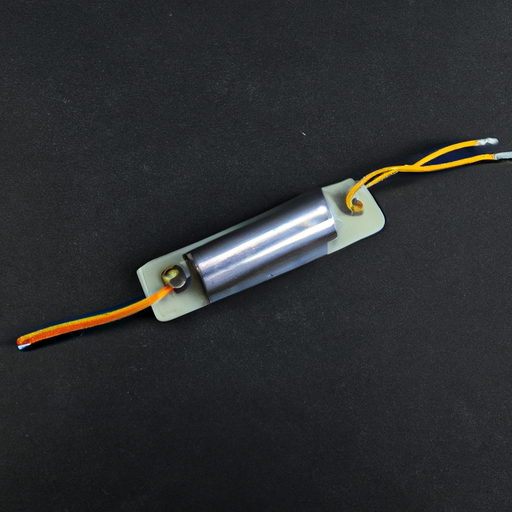

Battery holder pins are designed to securely hold batteries in place while providing a reliable electrical connection. They come in various types, including spring-loaded pins, solderable pins, and snap-fit designs, each tailored for specific applications. The materials used in manufacturing these pins typically include metals like copper and nickel, which offer excellent electrical conductivity and resistance to corrosion.

B. Design Considerations

When designing battery holder pins, several factors must be considered to ensure optimal performance. Size and compatibility are critical, as the pins must fit snugly within the battery holder and align with the battery terminals. Electrical conductivity and resistance are also vital, as poor connections can lead to energy loss and device malfunction. Additionally, durability and longevity are essential, especially in applications where the pins will be subjected to frequent use or harsh environmental conditions.

III. Main Application Directions

A. Consumer Electronics

Battery holder pins are ubiquitous in consumer electronics, powering a wide range of devices.

1. **Mobile Devices**: Smartphones and tablets rely on battery holder pins to maintain a stable connection between the battery and the device's internal circuitry. As mobile technology advances, the demand for smaller, more efficient battery holder pins has increased, leading to innovations in design and materials.

2. **Laptops and Tablets**: Similar to mobile devices, laptops and tablets utilize battery holder pins to ensure reliable power delivery. The trend towards thinner and lighter devices has prompted manufacturers to develop more compact battery holder pins that do not compromise performance.

3. **Wearable Technology**: Wearable devices, such as smartwatches and fitness trackers, also depend on battery holder pins. These devices require lightweight and efficient power solutions, making the design of battery holder pins even more critical.

B. Automotive Industry

The automotive industry has seen a significant shift towards electric and hybrid vehicles, increasing the demand for advanced battery holder pins.

1. **Electric Vehicles (EVs)**: In EVs, battery holder pins are essential for connecting the high-capacity batteries that power the vehicle. These pins must be designed to handle high currents and provide a secure connection to ensure safety and performance.

2. **Traditional Internal Combustion Engine Vehicles**: Even in conventional vehicles, battery holder pins are used in various applications, including starting systems and electronic control units. The reliability of these pins is crucial for the overall performance of the vehicle.

3. **Automotive Accessories**: Battery holder pins are also found in automotive accessories, such as GPS devices and dash cams, where they facilitate power connections.

C. Industrial Applications

Battery holder pins play a vital role in various industrial applications, where reliability and performance are paramount.

1. **Robotics and Automation**: In robotics, battery holder pins are used to connect power sources to robotic systems. The ability to quickly replace batteries is essential in maintaining operational efficiency.

2. **Power Tools**: Cordless power tools rely on battery holder pins to connect rechargeable batteries. The design of these pins must ensure a secure fit to withstand the rigors of heavy use.

3. **Industrial Sensors**: Many industrial sensors require battery power to operate. Battery holder pins provide a reliable connection, ensuring that these sensors function correctly in demanding environments.

D. Medical Devices

The medical field has unique requirements for battery holder pins, where reliability and safety are critical.

1. **Portable Medical Equipment**: Devices such as portable ultrasound machines and blood glucose monitors rely on battery holder pins for power. These pins must be designed to ensure a secure connection while being easy to replace.

2. **Implantable Devices**: In implantable medical devices, such as pacemakers, battery holder pins must meet stringent safety and reliability standards. The materials used must be biocompatible to prevent adverse reactions in the body.

3. **Diagnostic Tools**: Battery holder pins are also used in diagnostic tools, where they provide the necessary power for accurate readings and analysis.

E. Renewable Energy Systems

As the world shifts towards renewable energy, battery holder pins are becoming increasingly important in energy storage systems.

1. **Solar Power Storage**: Battery holder pins are used in solar power storage systems to connect batteries that store energy generated from solar panels. The reliability of these connections is crucial for efficient energy management.

2. **Wind Energy Systems**: Similar to solar systems, wind energy systems rely on battery holder pins to connect energy storage solutions. These pins must be designed to handle varying environmental conditions.

3. **Energy Management Systems**: In energy management systems, battery holder pins facilitate the connection between batteries and control systems, ensuring efficient energy distribution.

IV. Emerging Trends and Innovations

As technology advances, several trends are shaping the future of battery holder pins.

A. Miniaturization of Battery Holder Pins

The trend towards smaller electronic devices has led to the miniaturization of battery holder pins. Manufacturers are developing more compact designs that maintain performance while reducing size.

B. Smart Battery Holders with Integrated Technology

Innovations in smart technology are leading to the development of battery holders with integrated features, such as monitoring battery health and charge levels. These smart battery holders can provide valuable data to users and enhance the overall user experience.

C. Sustainable Materials and Eco-Friendly Designs

With growing concerns about environmental impact, manufacturers are exploring sustainable materials for battery holder pins. Eco-friendly designs aim to reduce waste and promote recycling, aligning with global sustainability goals.

D. Enhanced Safety Features

As the demand for safety in electronic devices increases, battery holder pins are being designed with enhanced safety features. These may include mechanisms to prevent short circuits and overheating, ensuring the safe operation of devices.

V. Challenges and Considerations

Despite their importance, battery holder pins face several challenges.

A. Compatibility Issues with Different Battery Types

One of the primary challenges is ensuring compatibility with various battery types. As new battery technologies emerge, battery holder pins must be adaptable to accommodate these changes.

B. Environmental Impact and Recycling

The environmental impact of battery holder pins, particularly in terms of waste and recycling, is a growing concern. Manufacturers must consider the lifecycle of these components and develop strategies for responsible disposal.

C. Cost vs. Performance Trade-offs

Balancing cost and performance is a constant challenge in the design of battery holder pins. While high-quality materials and advanced designs can enhance performance, they may also increase production costs.

D. Regulatory Standards and Compliance

Battery holder pins must comply with various regulatory standards, particularly in industries such as medical and automotive. Ensuring compliance can be a complex and time-consuming process.

VI. Conclusion

In summary, battery holder pins are integral components in a wide range of applications, from consumer electronics to renewable energy systems. Their design and functionality are critical to the performance and reliability of electronic devices. As technology continues to evolve, the future of battery holder pins looks promising, with emerging trends in miniaturization, smart technology, and sustainability shaping their development. Understanding the main application directions of battery holder pins highlights their importance in modern technology and underscores the need for continued innovation in this essential field.

VII. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Specifications

4. Relevant Online Resources

This blog post provides a comprehensive overview of the main application direction of battery holder pins, emphasizing their significance across various industries and the challenges they face in an ever-evolving technological landscape.

What is the Main Application Direction of the Battery Holder Pin?

I. Introduction

In the realm of electronics, the battery holder pin plays a crucial role in ensuring that devices receive the power they need to function effectively. A battery holder pin is a small yet essential component that connects batteries to electronic circuits, allowing for the transfer of electrical energy. As technology continues to evolve, the importance of battery holder pins in various electronic devices cannot be overstated. This blog post will explore the main application directions of battery holder pins, highlighting their significance across different industries.

II. Understanding Battery Holder Pins

A. Description and Functionality

Battery holder pins are designed to securely hold batteries in place while providing a reliable electrical connection. They come in various types, including spring-loaded pins, solderable pins, and snap-fit designs, each tailored for specific applications. The materials used in manufacturing these pins typically include metals like copper and nickel, which offer excellent electrical conductivity and resistance to corrosion.

B. Design Considerations

When designing battery holder pins, several factors must be considered to ensure optimal performance. Size and compatibility are critical, as the pins must fit snugly within the battery holder and align with the battery terminals. Electrical conductivity and resistance are also vital, as poor connections can lead to energy loss and device malfunction. Additionally, durability and longevity are essential, especially in applications where the pins will be subjected to frequent use or harsh environmental conditions.

III. Main Application Directions

A. Consumer Electronics

Battery holder pins are ubiquitous in consumer electronics, powering a wide range of devices.

1. **Mobile Devices**: Smartphones and tablets rely on battery holder pins to maintain a stable connection between the battery and the device's internal circuitry. As mobile technology advances, the demand for smaller, more efficient battery holder pins has increased, leading to innovations in design and materials.

2. **Laptops and Tablets**: Similar to mobile devices, laptops and tablets utilize battery holder pins to ensure reliable power delivery. The trend towards thinner and lighter devices has prompted manufacturers to develop more compact battery holder pins that do not compromise performance.

3. **Wearable Technology**: Wearable devices, such as smartwatches and fitness trackers, also depend on battery holder pins. These devices require lightweight and efficient power solutions, making the design of battery holder pins even more critical.

B. Automotive Industry

The automotive industry has seen a significant shift towards electric and hybrid vehicles, increasing the demand for advanced battery holder pins.

1. **Electric Vehicles (EVs)**: In EVs, battery holder pins are essential for connecting the high-capacity batteries that power the vehicle. These pins must be designed to handle high currents and provide a secure connection to ensure safety and performance.

2. **Traditional Internal Combustion Engine Vehicles**: Even in conventional vehicles, battery holder pins are used in various applications, including starting systems and electronic control units. The reliability of these pins is crucial for the overall performance of the vehicle.

3. **Automotive Accessories**: Battery holder pins are also found in automotive accessories, such as GPS devices and dash cams, where they facilitate power connections.

C. Industrial Applications

Battery holder pins play a vital role in various industrial applications, where reliability and performance are paramount.

1. **Robotics and Automation**: In robotics, battery holder pins are used to connect power sources to robotic systems. The ability to quickly replace batteries is essential in maintaining operational efficiency.

2. **Power Tools**: Cordless power tools rely on battery holder pins to connect rechargeable batteries. The design of these pins must ensure a secure fit to withstand the rigors of heavy use.

3. **Industrial Sensors**: Many industrial sensors require battery power to operate. Battery holder pins provide a reliable connection, ensuring that these sensors function correctly in demanding environments.

D. Medical Devices

The medical field has unique requirements for battery holder pins, where reliability and safety are critical.

1. **Portable Medical Equipment**: Devices such as portable ultrasound machines and blood glucose monitors rely on battery holder pins for power. These pins must be designed to ensure a secure connection while being easy to replace.

2. **Implantable Devices**: In implantable medical devices, such as pacemakers, battery holder pins must meet stringent safety and reliability standards. The materials used must be biocompatible to prevent adverse reactions in the body.

3. **Diagnostic Tools**: Battery holder pins are also used in diagnostic tools, where they provide the necessary power for accurate readings and analysis.

E. Renewable Energy Systems

As the world shifts towards renewable energy, battery holder pins are becoming increasingly important in energy storage systems.

1. **Solar Power Storage**: Battery holder pins are used in solar power storage systems to connect batteries that store energy generated from solar panels. The reliability of these connections is crucial for efficient energy management.

2. **Wind Energy Systems**: Similar to solar systems, wind energy systems rely on battery holder pins to connect energy storage solutions. These pins must be designed to handle varying environmental conditions.

3. **Energy Management Systems**: In energy management systems, battery holder pins facilitate the connection between batteries and control systems, ensuring efficient energy distribution.

IV. Emerging Trends and Innovations

As technology advances, several trends are shaping the future of battery holder pins.

A. Miniaturization of Battery Holder Pins

The trend towards smaller electronic devices has led to the miniaturization of battery holder pins. Manufacturers are developing more compact designs that maintain performance while reducing size.

B. Smart Battery Holders with Integrated Technology

Innovations in smart technology are leading to the development of battery holders with integrated features, such as monitoring battery health and charge levels. These smart battery holders can provide valuable data to users and enhance the overall user experience.

C. Sustainable Materials and Eco-Friendly Designs

With growing concerns about environmental impact, manufacturers are exploring sustainable materials for battery holder pins. Eco-friendly designs aim to reduce waste and promote recycling, aligning with global sustainability goals.

D. Enhanced Safety Features

As the demand for safety in electronic devices increases, battery holder pins are being designed with enhanced safety features. These may include mechanisms to prevent short circuits and overheating, ensuring the safe operation of devices.

V. Challenges and Considerations

Despite their importance, battery holder pins face several challenges.

A. Compatibility Issues with Different Battery Types

One of the primary challenges is ensuring compatibility with various battery types. As new battery technologies emerge, battery holder pins must be adaptable to accommodate these changes.

B. Environmental Impact and Recycling

The environmental impact of battery holder pins, particularly in terms of waste and recycling, is a growing concern. Manufacturers must consider the lifecycle of these components and develop strategies for responsible disposal.

C. Cost vs. Performance Trade-offs

Balancing cost and performance is a constant challenge in the design of battery holder pins. While high-quality materials and advanced designs can enhance performance, they may also increase production costs.

D. Regulatory Standards and Compliance

Battery holder pins must comply with various regulatory standards, particularly in industries such as medical and automotive. Ensuring compliance can be a complex and time-consuming process.

VI. Conclusion

In summary, battery holder pins are integral components in a wide range of applications, from consumer electronics to renewable energy systems. Their design and functionality are critical to the performance and reliability of electronic devices. As technology continues to evolve, the future of battery holder pins looks promising, with emerging trends in miniaturization, smart technology, and sustainability shaping their development. Understanding the main application directions of battery holder pins highlights their importance in modern technology and underscores the need for continued innovation in this essential field.

VII. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Specifications

4. Relevant Online Resources

This blog post provides a comprehensive overview of the main application direction of battery holder pins, emphasizing their significance across various industries and the challenges they face in an ever-evolving technological landscape.