Understanding Battery Holder Terminals

I. Introduction

In the world of electronics, the components that facilitate the flow of electricity are crucial for the functionality of devices. Among these components, battery holder terminals play a vital role. A battery holder terminal is a conductive point that connects a battery to an electronic circuit, ensuring that power is delivered efficiently. Understanding battery holder terminals is essential for anyone involved in electronics, whether you're a hobbyist, a professional engineer, or simply a curious consumer. This article aims to provide a comprehensive overview of battery holder terminals, their types, materials, design considerations, and their significance in modern electronic devices.

II. Overview of Battery Holders

A. Definition and Function of Battery Holders

Battery holders are devices designed to securely hold batteries in place while providing electrical connections to the circuit. They come in various shapes and sizes, accommodating different battery types, including AA, AAA, 9V, and more. The primary function of a battery holder is to ensure that the battery remains connected to the circuit, allowing for a stable power supply.

B. Types of Battery Holders

1. **Fixed Battery Holders**: These holders are designed to hold batteries in a fixed position. They are often used in applications where the battery is not intended to be removed frequently, such as in remote controls or wall clocks.

2. **Spring-loaded Battery Holders**: These holders use springs to maintain contact with the battery terminals. They are commonly found in devices that require easy battery replacement, such as flashlights and portable electronics.

3. **Clip-style Battery Holders**: These holders use clips to secure the battery in place. They are often used in custom electronic projects and prototyping, allowing for quick battery changes.

C. Common Applications of Battery Holders

Battery holders are ubiquitous in electronic devices, ranging from simple toys to complex machinery. They are used in remote controls, cameras, medical devices, and even electric vehicles, highlighting their versatility and importance in various applications.

III. Understanding Battery Holder Terminals

A. Definition of Battery Holder Terminals

Battery holder terminals are the conductive points within a battery holder that connect the battery to the electronic circuit. They are essential for ensuring that electrical current flows from the battery to the device, enabling it to function properly.

B. Role of Terminals in Battery Holders

The terminals serve as the interface between the battery and the circuit. They must provide a reliable connection to ensure that the device receives the necessary power. Poor connections can lead to device malfunction, reduced performance, or even damage to the components.

C. Types of Terminals

1. **Positive Terminals**: These terminals connect to the positive side of the battery, allowing current to flow into the circuit.

2. **Negative Terminals**: These terminals connect to the negative side of the battery, completing the circuit and allowing current to return to the battery.

3. **Multi-terminal Configurations**: Some battery holders feature multiple terminals to accommodate different battery configurations or to provide additional connections for other components.

IV. Materials Used in Battery Holder Terminals

A. Common Materials

Battery holder terminals are typically made from conductive materials such as copper or nickel, which offer excellent electrical conductivity. The housing or insulation around the terminals is often made from durable plastics to prevent short circuits and ensure safety.

B. Importance of Material Selection for Conductivity and Durability

The choice of materials is critical for the performance and longevity of battery holder terminals. High-quality conductive materials ensure minimal resistance, allowing for efficient power transfer. Additionally, durable materials can withstand wear and tear, ensuring that the terminals maintain their functionality over time.

C. Environmental Considerations

As environmental concerns grow, manufacturers are increasingly considering the sustainability of materials used in battery holder terminals. This includes using recyclable materials and minimizing the environmental impact of production processes.

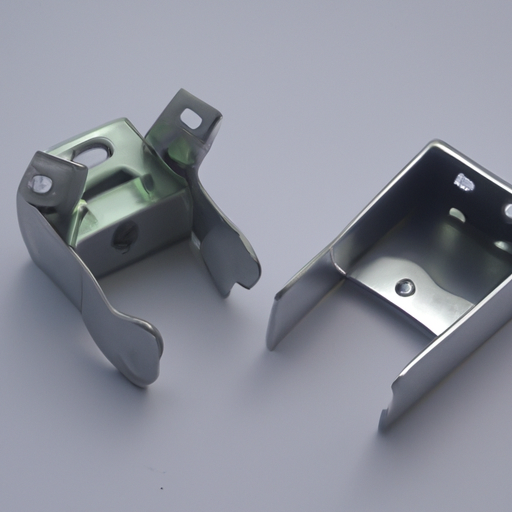

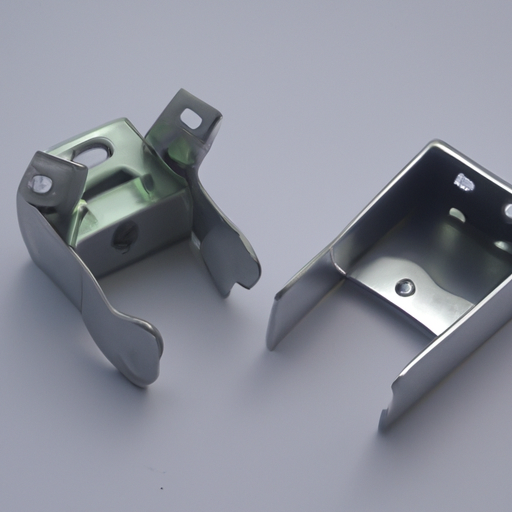

V. Design and Construction of Battery Holder Terminals

A. Design Considerations for Battery Holder Terminals

1. **Size and Shape**: The design of battery holder terminals must accommodate the specific battery type and ensure a secure fit. The size and shape can also affect the ease of installation and removal.

2. **Compatibility with Battery Types**: Different batteries have varying terminal configurations, so battery holder terminals must be designed to match these specifications for optimal performance.

B. Manufacturing Processes

1. **Stamping**: This process involves cutting and shaping metal sheets into the desired terminal shapes. Stamping is efficient for mass production and ensures uniformity in terminal design.

2. **Injection Molding**: This process is used to create the plastic components of battery holders, including the housing that encases the terminals. Injection molding allows for complex shapes and designs.

C. Quality Control Measures

To ensure the reliability and safety of battery holder terminals, manufacturers implement strict quality control measures. This includes testing for conductivity, durability, and compliance with safety standards.

VI. Electrical Properties of Battery Holder Terminals

A. Conductivity and Resistance

The conductivity of battery holder terminals is crucial for efficient power transfer. Low resistance is essential to minimize energy loss and ensure that devices operate effectively.

B. Voltage Ratings

Battery holder terminals must be rated for the appropriate voltage levels to prevent breakdown or failure. Understanding the voltage requirements of the connected devices is essential for selecting the right battery holder.

C. Current Ratings

Current ratings indicate the maximum amount of current that the terminals can safely handle. Exceeding these ratings can lead to overheating and potential damage to the device.

D. Impact of Terminal Design on Electrical Performance

The design of battery holder terminals can significantly impact their electrical performance. Factors such as contact area, shape, and material can influence resistance and overall efficiency.

VII. Installation and Maintenance of Battery Holder Terminals

A. Proper Installation Techniques

Correct installation of battery holder terminals is essential for ensuring a reliable connection. This includes ensuring that terminals are clean, free of corrosion, and securely attached to the battery and circuit.

B. Common Issues and Troubleshooting

Common issues with battery holder terminals include poor connections, corrosion, and physical damage. Troubleshooting these problems often involves inspecting the terminals for wear and ensuring that they are properly connected.

C. Maintenance Tips for Longevity

To extend the life of battery holder terminals, regular maintenance is recommended. This includes cleaning terminals to remove corrosion, checking for loose connections, and replacing damaged components as needed.

VIII. Safety Considerations

A. Risks Associated with Improper Use

Improper use of battery holder terminals can lead to short circuits, overheating, and even fires. It is essential to follow safety guidelines when handling batteries and terminals.

B. Safety Standards and Regulations

Various safety standards govern the design and use of battery holder terminals. Compliance with these regulations is crucial for ensuring the safety of electronic devices.

C. Best Practices for Safe Handling

Best practices for handling battery holder terminals include wearing protective gear, avoiding contact with conductive surfaces, and ensuring that batteries are installed correctly.

IX. Future Trends in Battery Holder Terminals

A. Innovations in Design and Materials

As technology advances, innovations in the design and materials used for battery holder terminals are emerging. This includes the development of more efficient conductive materials and designs that enhance performance.

B. Impact of Technology Advancements on Battery Holder Terminals

The rise of new technologies, such as electric vehicles and renewable energy systems, is driving demand for more advanced battery holder terminals. These applications require terminals that can handle higher voltages and currents.

C. Predictions for Future Applications

As the demand for portable and efficient power sources grows, battery holder terminals will continue to evolve. Future applications may include integration with smart technologies and enhanced safety features.

X. Conclusion

Battery holder terminals are a critical component in the functioning of electronic devices, providing the necessary connections for power delivery. Understanding their design, materials, and electrical properties is essential for anyone involved in electronics. As technology continues to advance, the importance of battery holder terminals will only grow, making it crucial for individuals and industries to stay informed about their development and applications. Whether you're a hobbyist or a professional, exploring the world of battery holder terminals can lead to a deeper appreciation of the technology that powers our devices.

XI. References

For further reading on battery technology and components, consider exploring the following resources:

1. "Battery Technology Handbook" by H.A. Kiehne

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

3. Websites such as the Battery University and IEEE Xplore for the latest research and articles on battery technology.

By understanding battery holder terminals, you can enhance your knowledge of electronics and contribute to the development of innovative solutions in this ever-evolving field.

Understanding Battery Holder Terminals

I. Introduction

In the world of electronics, the components that facilitate the flow of electricity are crucial for the functionality of devices. Among these components, battery holder terminals play a vital role. A battery holder terminal is a conductive point that connects a battery to an electronic circuit, ensuring that power is delivered efficiently. Understanding battery holder terminals is essential for anyone involved in electronics, whether you're a hobbyist, a professional engineer, or simply a curious consumer. This article aims to provide a comprehensive overview of battery holder terminals, their types, materials, design considerations, and their significance in modern electronic devices.

II. Overview of Battery Holders

A. Definition and Function of Battery Holders

Battery holders are devices designed to securely hold batteries in place while providing electrical connections to the circuit. They come in various shapes and sizes, accommodating different battery types, including AA, AAA, 9V, and more. The primary function of a battery holder is to ensure that the battery remains connected to the circuit, allowing for a stable power supply.

B. Types of Battery Holders

1. **Fixed Battery Holders**: These holders are designed to hold batteries in a fixed position. They are often used in applications where the battery is not intended to be removed frequently, such as in remote controls or wall clocks.

2. **Spring-loaded Battery Holders**: These holders use springs to maintain contact with the battery terminals. They are commonly found in devices that require easy battery replacement, such as flashlights and portable electronics.

3. **Clip-style Battery Holders**: These holders use clips to secure the battery in place. They are often used in custom electronic projects and prototyping, allowing for quick battery changes.

C. Common Applications of Battery Holders

Battery holders are ubiquitous in electronic devices, ranging from simple toys to complex machinery. They are used in remote controls, cameras, medical devices, and even electric vehicles, highlighting their versatility and importance in various applications.

III. Understanding Battery Holder Terminals

A. Definition of Battery Holder Terminals

Battery holder terminals are the conductive points within a battery holder that connect the battery to the electronic circuit. They are essential for ensuring that electrical current flows from the battery to the device, enabling it to function properly.

B. Role of Terminals in Battery Holders

The terminals serve as the interface between the battery and the circuit. They must provide a reliable connection to ensure that the device receives the necessary power. Poor connections can lead to device malfunction, reduced performance, or even damage to the components.

C. Types of Terminals

1. **Positive Terminals**: These terminals connect to the positive side of the battery, allowing current to flow into the circuit.

2. **Negative Terminals**: These terminals connect to the negative side of the battery, completing the circuit and allowing current to return to the battery.

3. **Multi-terminal Configurations**: Some battery holders feature multiple terminals to accommodate different battery configurations or to provide additional connections for other components.

IV. Materials Used in Battery Holder Terminals

A. Common Materials

Battery holder terminals are typically made from conductive materials such as copper or nickel, which offer excellent electrical conductivity. The housing or insulation around the terminals is often made from durable plastics to prevent short circuits and ensure safety.

B. Importance of Material Selection for Conductivity and Durability

The choice of materials is critical for the performance and longevity of battery holder terminals. High-quality conductive materials ensure minimal resistance, allowing for efficient power transfer. Additionally, durable materials can withstand wear and tear, ensuring that the terminals maintain their functionality over time.

C. Environmental Considerations

As environmental concerns grow, manufacturers are increasingly considering the sustainability of materials used in battery holder terminals. This includes using recyclable materials and minimizing the environmental impact of production processes.

V. Design and Construction of Battery Holder Terminals

A. Design Considerations for Battery Holder Terminals

1. **Size and Shape**: The design of battery holder terminals must accommodate the specific battery type and ensure a secure fit. The size and shape can also affect the ease of installation and removal.

2. **Compatibility with Battery Types**: Different batteries have varying terminal configurations, so battery holder terminals must be designed to match these specifications for optimal performance.

B. Manufacturing Processes

1. **Stamping**: This process involves cutting and shaping metal sheets into the desired terminal shapes. Stamping is efficient for mass production and ensures uniformity in terminal design.

2. **Injection Molding**: This process is used to create the plastic components of battery holders, including the housing that encases the terminals. Injection molding allows for complex shapes and designs.

C. Quality Control Measures

To ensure the reliability and safety of battery holder terminals, manufacturers implement strict quality control measures. This includes testing for conductivity, durability, and compliance with safety standards.

VI. Electrical Properties of Battery Holder Terminals

A. Conductivity and Resistance

The conductivity of battery holder terminals is crucial for efficient power transfer. Low resistance is essential to minimize energy loss and ensure that devices operate effectively.

B. Voltage Ratings

Battery holder terminals must be rated for the appropriate voltage levels to prevent breakdown or failure. Understanding the voltage requirements of the connected devices is essential for selecting the right battery holder.

C. Current Ratings

Current ratings indicate the maximum amount of current that the terminals can safely handle. Exceeding these ratings can lead to overheating and potential damage to the device.

D. Impact of Terminal Design on Electrical Performance

The design of battery holder terminals can significantly impact their electrical performance. Factors such as contact area, shape, and material can influence resistance and overall efficiency.

VII. Installation and Maintenance of Battery Holder Terminals

A. Proper Installation Techniques

Correct installation of battery holder terminals is essential for ensuring a reliable connection. This includes ensuring that terminals are clean, free of corrosion, and securely attached to the battery and circuit.

B. Common Issues and Troubleshooting

Common issues with battery holder terminals include poor connections, corrosion, and physical damage. Troubleshooting these problems often involves inspecting the terminals for wear and ensuring that they are properly connected.

C. Maintenance Tips for Longevity

To extend the life of battery holder terminals, regular maintenance is recommended. This includes cleaning terminals to remove corrosion, checking for loose connections, and replacing damaged components as needed.

VIII. Safety Considerations

A. Risks Associated with Improper Use

Improper use of battery holder terminals can lead to short circuits, overheating, and even fires. It is essential to follow safety guidelines when handling batteries and terminals.

B. Safety Standards and Regulations

Various safety standards govern the design and use of battery holder terminals. Compliance with these regulations is crucial for ensuring the safety of electronic devices.

C. Best Practices for Safe Handling

Best practices for handling battery holder terminals include wearing protective gear, avoiding contact with conductive surfaces, and ensuring that batteries are installed correctly.

IX. Future Trends in Battery Holder Terminals

A. Innovations in Design and Materials

As technology advances, innovations in the design and materials used for battery holder terminals are emerging. This includes the development of more efficient conductive materials and designs that enhance performance.

B. Impact of Technology Advancements on Battery Holder Terminals

The rise of new technologies, such as electric vehicles and renewable energy systems, is driving demand for more advanced battery holder terminals. These applications require terminals that can handle higher voltages and currents.

C. Predictions for Future Applications

As the demand for portable and efficient power sources grows, battery holder terminals will continue to evolve. Future applications may include integration with smart technologies and enhanced safety features.

X. Conclusion

Battery holder terminals are a critical component in the functioning of electronic devices, providing the necessary connections for power delivery. Understanding their design, materials, and electrical properties is essential for anyone involved in electronics. As technology continues to advance, the importance of battery holder terminals will only grow, making it crucial for individuals and industries to stay informed about their development and applications. Whether you're a hobbyist or a professional, exploring the world of battery holder terminals can lead to a deeper appreciation of the technology that powers our devices.

XI. References

For further reading on battery technology and components, consider exploring the following resources:

1. "Battery Technology Handbook" by H.A. Kiehne

2. "The Art of Electronics" by Paul Horowitz and Winfield Hill

3. Websites such as the Battery University and IEEE Xplore for the latest research and articles on battery technology.

By understanding battery holder terminals, you can enhance your knowledge of electronics and contribute to the development of innovative solutions in this ever-evolving field.