What Components and Modules Does the 4P Battery Holder Contain?

I. Introduction

In the world of electronics, battery holders play a crucial role in ensuring that devices receive the power they need to function effectively. Among the various configurations available, the 4P battery holder stands out due to its ability to accommodate four parallel cells, providing a reliable power source for a wide range of applications. This blog post will explore the components and modules that make up a 4P battery holder, highlighting their importance and functionality in electronic devices.

II. Understanding Battery Holders

A. Purpose of Battery Holders

Battery holders serve as the interface between batteries and electronic devices. They securely hold batteries in place, ensuring proper electrical contact while allowing for easy replacement. This is particularly important in devices that require frequent battery changes, as it enhances user convenience and device longevity.

B. Types of Battery Holders

Battery holders can be categorized into two main types: single cell holders and multi-cell holders. Single cell holders are designed for one battery, while multi-cell holders can accommodate multiple batteries, either in series or parallel configurations.

C. Introduction to the 4P Configuration

1. Explanation of "4P" (4 Parallel Cells)

The term "4P" refers to a configuration where four batteries are connected in parallel. This setup allows for increased capacity while maintaining the same voltage as a single cell. For instance, using four 1.5V AA batteries in a 4P configuration will still yield 1.5V but with a higher total capacity, making it ideal for devices that require more power.

2. Applications of 4P Battery Holders

4P battery holders are commonly used in various applications, including consumer electronics, industrial equipment, and renewable energy systems. Their ability to provide a stable power supply makes them suitable for devices such as remote controls, toys, and portable electronics.

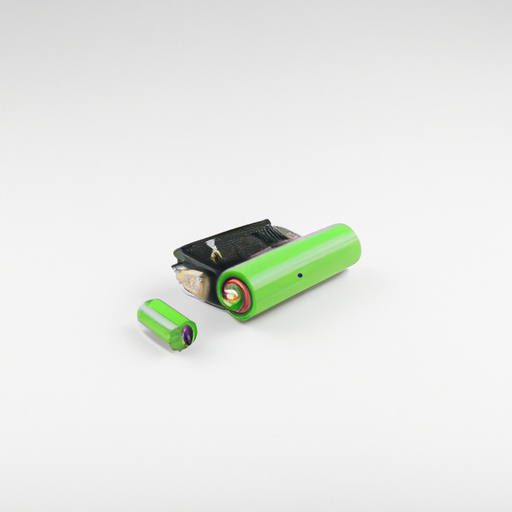

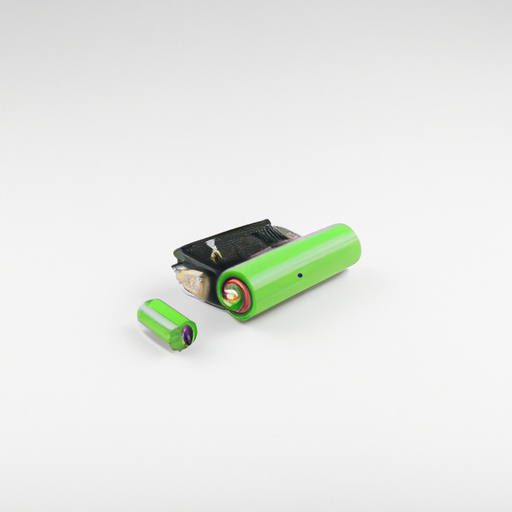

III. Key Components of a 4P Battery Holder

A. Battery Contacts

1. Function and Importance

Battery contacts are essential components of a battery holder, as they establish the electrical connection between the batteries and the device. Proper contact ensures efficient power transfer, which is critical for the device's performance.

2. Types of Contacts (Spring-loaded, Flat, etc.)

Battery contacts can be categorized into several types, including spring-loaded contacts and flat contacts. Spring-loaded contacts provide a more secure connection by adjusting to the battery's position, while flat contacts are simpler and often used in low-cost applications.

B. Holder Frame

1. Material Composition (Plastic, Metal)

The holder frame is the structure that houses the batteries and contacts. It is typically made from materials such as plastic or metal. Plastic frames are lightweight and cost-effective, while metal frames offer enhanced durability and heat dissipation.

2. Design Considerations (Size, Shape)

The design of the holder frame is crucial for ensuring compatibility with various battery sizes and shapes. A well-designed frame will securely hold the batteries in place while allowing for easy insertion and removal.

C. Connection Terminals

1. Types of Terminals (Solder, Snap-in)

Connection terminals are the points where the battery holder connects to the electronic circuit. They can be soldered directly to the circuit board or designed as snap-in terminals for easy installation. The choice of terminal type depends on the specific application and design requirements.

2. Role in Electrical Connectivity

Connection terminals play a vital role in ensuring reliable electrical connectivity. They must be designed to handle the current load and provide a stable connection to prevent power loss or device malfunction.

D. Insulation and Safety Features

1. Importance of Insulation

Insulation is critical in battery holders to prevent short circuits and protect against electrical shock. Proper insulation materials help ensure that the holder operates safely and efficiently.

2. Safety Mechanisms (Fuses, Thermal Cutoffs)

Many 4P battery holders incorporate safety mechanisms such as fuses and thermal cutoffs. These features protect the device from overcurrent and overheating, enhancing overall safety and reliability.

IV. Modules Associated with 4P Battery Holders

A. Battery Management Systems (BMS)

1. Overview of BMS

A Battery Management System (BMS) is an electronic system that manages a rechargeable battery. It monitors the battery's state, controls its charging and discharging, and ensures safety by preventing overcharging and deep discharging.

2. Role in Monitoring and Protection

In a 4P battery holder, a BMS plays a crucial role in monitoring the health of each cell, balancing the charge across the cells, and providing protection against potential hazards. This ensures that the batteries operate efficiently and have a longer lifespan.

B. Charging Modules

1. Types of Charging Modules

Charging modules are designed to recharge batteries safely and efficiently. They can vary in complexity, from simple linear chargers to more advanced switch-mode power supplies that optimize charging times and efficiency.

2. Integration with 4P Holders

Charging modules can be integrated into 4P battery holders to provide a complete power solution. This integration allows for seamless charging and discharging cycles, making it easier for users to maintain their devices.

C. Voltage Regulation Modules

1. Importance of Voltage Regulation

Voltage regulation is essential in electronic devices to ensure that the components receive a stable voltage. Fluctuations in voltage can lead to device malfunction or damage.

2. Types of Voltage Regulators Used

Various types of voltage regulators can be used with 4P battery holders, including linear regulators and switching regulators. The choice of regulator depends on the specific voltage requirements of the device and the efficiency needed.

D. Indicator Modules

1. LED Indicators for Battery Status

Indicator modules, such as LED lights, can be integrated into 4P battery holders to provide users with real-time information about the battery status. These indicators can show whether the batteries are charged, discharging, or need replacement.

2. Integration with the Holder

Integrating indicator modules with the battery holder enhances user experience by providing visual feedback on battery health and status, allowing users to make informed decisions about battery maintenance.

V. Assembly and Integration

A. How Components Fit Together

The assembly of a 4P battery holder involves fitting together various components, including the holder frame, battery contacts, connection terminals, and safety features. Each component must be carefully designed to ensure compatibility and functionality.

B. Importance of Proper Assembly

Proper assembly is crucial for the performance and safety of the battery holder. Misalignment or poor connections can lead to power loss, overheating, or even device failure.

C. Common Issues and Troubleshooting

Common issues with 4P battery holders include poor contact, corrosion, and mechanical failure. Troubleshooting these issues often involves inspecting the connections, cleaning contacts, and ensuring that the holder is properly assembled.

VI. Applications of 4P Battery Holders

A. Consumer Electronics

4P battery holders are widely used in consumer electronics, including remote controls, portable speakers, and toys. Their ability to provide a stable power supply makes them ideal for devices that require reliable performance.

B. Industrial Applications

In industrial settings, 4P battery holders are used in equipment such as power tools, sensors, and automation devices. Their robustness and reliability are essential for maintaining operational efficiency.

C. Renewable Energy Systems

4P battery holders are also utilized in renewable energy systems, such as solar power storage solutions. They help manage the energy produced by solar panels, ensuring that it is stored and used efficiently.

D. Robotics and Automation

In robotics and automation, 4P battery holders provide the necessary power for various components, including motors, sensors, and control systems. Their ability to deliver consistent power is critical for the performance of robotic systems.

VII. Conclusion

In summary, the 4P battery holder is a vital component in many electronic devices, providing a reliable power source through its carefully designed components and modules. Understanding the various elements that make up a 4P battery holder, from battery contacts to safety features, is essential for anyone involved in electronics design or maintenance. As technology continues to evolve, we can expect to see advancements in battery holder technology, enhancing their efficiency and safety. Ultimately, a solid understanding of battery holders is crucial for ensuring the longevity and performance of electronic devices.

VIII. References

A. Suggested Reading and Resources

1. "Battery Holders: A Comprehensive Guide" - Electronics Weekly

2. "Understanding Battery Management Systems" - Battery University

B. Industry Standards and Guidelines

1. IEC 62133 - Safety requirements for portable sealed secondary cells

2. UL 2054 - Standard for Household and Commercial Batteries

This blog post provides a detailed overview of the components and modules found in a 4P battery holder, emphasizing their importance in various applications and the technology behind them.

What Components and Modules Does the 4P Battery Holder Contain?

I. Introduction

In the world of electronics, battery holders play a crucial role in ensuring that devices receive the power they need to function effectively. Among the various configurations available, the 4P battery holder stands out due to its ability to accommodate four parallel cells, providing a reliable power source for a wide range of applications. This blog post will explore the components and modules that make up a 4P battery holder, highlighting their importance and functionality in electronic devices.

II. Understanding Battery Holders

A. Purpose of Battery Holders

Battery holders serve as the interface between batteries and electronic devices. They securely hold batteries in place, ensuring proper electrical contact while allowing for easy replacement. This is particularly important in devices that require frequent battery changes, as it enhances user convenience and device longevity.

B. Types of Battery Holders

Battery holders can be categorized into two main types: single cell holders and multi-cell holders. Single cell holders are designed for one battery, while multi-cell holders can accommodate multiple batteries, either in series or parallel configurations.

C. Introduction to the 4P Configuration

1. Explanation of "4P" (4 Parallel Cells)

The term "4P" refers to a configuration where four batteries are connected in parallel. This setup allows for increased capacity while maintaining the same voltage as a single cell. For instance, using four 1.5V AA batteries in a 4P configuration will still yield 1.5V but with a higher total capacity, making it ideal for devices that require more power.

2. Applications of 4P Battery Holders

4P battery holders are commonly used in various applications, including consumer electronics, industrial equipment, and renewable energy systems. Their ability to provide a stable power supply makes them suitable for devices such as remote controls, toys, and portable electronics.

III. Key Components of a 4P Battery Holder

A. Battery Contacts

1. Function and Importance

Battery contacts are essential components of a battery holder, as they establish the electrical connection between the batteries and the device. Proper contact ensures efficient power transfer, which is critical for the device's performance.

2. Types of Contacts (Spring-loaded, Flat, etc.)

Battery contacts can be categorized into several types, including spring-loaded contacts and flat contacts. Spring-loaded contacts provide a more secure connection by adjusting to the battery's position, while flat contacts are simpler and often used in low-cost applications.

B. Holder Frame

1. Material Composition (Plastic, Metal)

The holder frame is the structure that houses the batteries and contacts. It is typically made from materials such as plastic or metal. Plastic frames are lightweight and cost-effective, while metal frames offer enhanced durability and heat dissipation.

2. Design Considerations (Size, Shape)

The design of the holder frame is crucial for ensuring compatibility with various battery sizes and shapes. A well-designed frame will securely hold the batteries in place while allowing for easy insertion and removal.

C. Connection Terminals

1. Types of Terminals (Solder, Snap-in)

Connection terminals are the points where the battery holder connects to the electronic circuit. They can be soldered directly to the circuit board or designed as snap-in terminals for easy installation. The choice of terminal type depends on the specific application and design requirements.

2. Role in Electrical Connectivity

Connection terminals play a vital role in ensuring reliable electrical connectivity. They must be designed to handle the current load and provide a stable connection to prevent power loss or device malfunction.

D. Insulation and Safety Features

1. Importance of Insulation

Insulation is critical in battery holders to prevent short circuits and protect against electrical shock. Proper insulation materials help ensure that the holder operates safely and efficiently.

2. Safety Mechanisms (Fuses, Thermal Cutoffs)

Many 4P battery holders incorporate safety mechanisms such as fuses and thermal cutoffs. These features protect the device from overcurrent and overheating, enhancing overall safety and reliability.

IV. Modules Associated with 4P Battery Holders

A. Battery Management Systems (BMS)

1. Overview of BMS

A Battery Management System (BMS) is an electronic system that manages a rechargeable battery. It monitors the battery's state, controls its charging and discharging, and ensures safety by preventing overcharging and deep discharging.

2. Role in Monitoring and Protection

In a 4P battery holder, a BMS plays a crucial role in monitoring the health of each cell, balancing the charge across the cells, and providing protection against potential hazards. This ensures that the batteries operate efficiently and have a longer lifespan.

B. Charging Modules

1. Types of Charging Modules

Charging modules are designed to recharge batteries safely and efficiently. They can vary in complexity, from simple linear chargers to more advanced switch-mode power supplies that optimize charging times and efficiency.

2. Integration with 4P Holders

Charging modules can be integrated into 4P battery holders to provide a complete power solution. This integration allows for seamless charging and discharging cycles, making it easier for users to maintain their devices.

C. Voltage Regulation Modules

1. Importance of Voltage Regulation

Voltage regulation is essential in electronic devices to ensure that the components receive a stable voltage. Fluctuations in voltage can lead to device malfunction or damage.

2. Types of Voltage Regulators Used

Various types of voltage regulators can be used with 4P battery holders, including linear regulators and switching regulators. The choice of regulator depends on the specific voltage requirements of the device and the efficiency needed.

D. Indicator Modules

1. LED Indicators for Battery Status

Indicator modules, such as LED lights, can be integrated into 4P battery holders to provide users with real-time information about the battery status. These indicators can show whether the batteries are charged, discharging, or need replacement.

2. Integration with the Holder

Integrating indicator modules with the battery holder enhances user experience by providing visual feedback on battery health and status, allowing users to make informed decisions about battery maintenance.

V. Assembly and Integration

A. How Components Fit Together

The assembly of a 4P battery holder involves fitting together various components, including the holder frame, battery contacts, connection terminals, and safety features. Each component must be carefully designed to ensure compatibility and functionality.

B. Importance of Proper Assembly

Proper assembly is crucial for the performance and safety of the battery holder. Misalignment or poor connections can lead to power loss, overheating, or even device failure.

C. Common Issues and Troubleshooting

Common issues with 4P battery holders include poor contact, corrosion, and mechanical failure. Troubleshooting these issues often involves inspecting the connections, cleaning contacts, and ensuring that the holder is properly assembled.

VI. Applications of 4P Battery Holders

A. Consumer Electronics

4P battery holders are widely used in consumer electronics, including remote controls, portable speakers, and toys. Their ability to provide a stable power supply makes them ideal for devices that require reliable performance.

B. Industrial Applications

In industrial settings, 4P battery holders are used in equipment such as power tools, sensors, and automation devices. Their robustness and reliability are essential for maintaining operational efficiency.

C. Renewable Energy Systems

4P battery holders are also utilized in renewable energy systems, such as solar power storage solutions. They help manage the energy produced by solar panels, ensuring that it is stored and used efficiently.

D. Robotics and Automation

In robotics and automation, 4P battery holders provide the necessary power for various components, including motors, sensors, and control systems. Their ability to deliver consistent power is critical for the performance of robotic systems.

VII. Conclusion

In summary, the 4P battery holder is a vital component in many electronic devices, providing a reliable power source through its carefully designed components and modules. Understanding the various elements that make up a 4P battery holder, from battery contacts to safety features, is essential for anyone involved in electronics design or maintenance. As technology continues to evolve, we can expect to see advancements in battery holder technology, enhancing their efficiency and safety. Ultimately, a solid understanding of battery holders is crucial for ensuring the longevity and performance of electronic devices.

VIII. References

A. Suggested Reading and Resources

1. "Battery Holders: A Comprehensive Guide" - Electronics Weekly

2. "Understanding Battery Management Systems" - Battery University

B. Industry Standards and Guidelines

1. IEC 62133 - Safety requirements for portable sealed secondary cells

2. UL 2054 - Standard for Household and Commercial Batteries

This blog post provides a detailed overview of the components and modules found in a 4P battery holder, emphasizing their importance in various applications and the technology behind them.