What are the Product Standards for Capacitor Pictures?

I. Introduction

Capacitors are essential components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from consumer electronics to industrial machinery. As the demand for capacitors continues to grow, so does the need for stringent product standards in their manufacturing and representation. This article aims to explore the product standards for capacitor pictures, emphasizing their importance in ensuring quality, reliability, and consumer trust.

II. Overview of Capacitors

A. Types of Capacitors

Capacitors come in various types, each designed for specific applications and performance characteristics:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are polarized and often used in power supply circuits.

2. **Ceramic Capacitors**: These non-polarized capacitors are widely used in high-frequency applications due to their stability and low losses.

3. **Film Capacitors**: Made from plastic film, these capacitors are known for their reliability and are commonly used in audio and power applications.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small package and are often used in portable electronics.

B. Applications of Capacitors

Capacitors find applications across various industries:

1. **Consumer Electronics**: Used in devices like smartphones, televisions, and computers to stabilize voltage and filter signals.

2. **Industrial Applications**: Employed in machinery for energy storage and power factor correction.

3. **Automotive Industry**: Used in electric vehicles and traditional cars for energy management and signal processing.

4. **Renewable Energy Systems**: Essential in solar inverters and wind turbines for energy storage and management.

III. Importance of Product Standards

Product standards are vital in the capacitor industry for several reasons:

A. Ensuring Quality and Reliability

Standards help manufacturers produce capacitors that meet specific performance criteria, ensuring that they function reliably in their intended applications.

B. Facilitating International Trade

With standardized products, manufacturers can sell their capacitors globally, reducing barriers to trade and fostering competition.

C. Protecting Consumers and Manufacturers

Standards protect consumers by ensuring that products are safe and perform as expected. They also protect manufacturers from liability by providing guidelines for compliance.

D. Enhancing Product Compatibility

Standardized capacitors are more likely to be compatible with various devices, reducing the risk of failure and enhancing user experience.

IV. Key Organizations and Standards

Several organizations play a crucial role in establishing product standards for capacitors:

A. International Electrotechnical Commission (IEC)

The IEC develops international standards for electrical and electronic devices, including capacitors. Specific IEC standards outline performance, safety, and testing requirements for various capacitor types.

B. Institute of Electrical and Electronics Engineers (IEEE)

IEEE standards focus on electrical and electronic engineering practices. Relevant standards for capacitors include guidelines for testing and performance evaluation.

C. Underwriters Laboratories (UL)

UL is known for its safety certification. Capacitors that meet UL standards are tested for safety and performance, providing assurance to consumers and manufacturers.

D. Other Relevant Organizations

1. **American National Standards Institute (ANSI)**: Develops standards for various industries, including electronics.

2. **European Committee for Electrotechnical Standardization (CENELEC)**: Focuses on standardization in the electrical and electronic sectors within Europe.

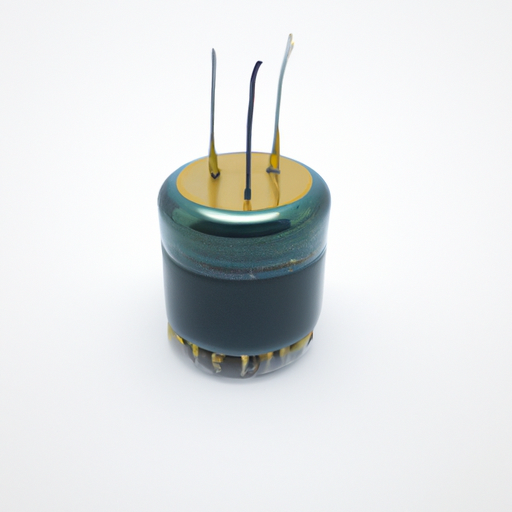

V. Product Standards for Capacitor Pictures

A. Visual Representation Requirements

The visual representation of capacitors is crucial for marketing and technical documentation. Key requirements include:

1. **Clarity and Resolution**: Images must be clear and high-resolution to accurately depict the capacitor's features.

2. **Color Accuracy**: Colors in the images should accurately represent the actual product to avoid misleading consumers.

3. **Size and Dimensions**: Images should include a scale or reference to convey the actual size of the capacitor.

B. Labeling and Markings

Proper labeling is essential for capacitor images:

1. **Manufacturer Information**: Images should include the manufacturer's name and logo for brand recognition.

2. **Electrical Specifications**: Key specifications, such as capacitance value and voltage rating, should be clearly visible.

3. **Safety Warnings and Certifications**: Any relevant safety certifications or warnings should be included in the image.

C. Compliance with Industry Standards

Images of capacitors should comply with industry standards, including:

1. **ISO Standards for Photography**: These standards ensure that images are captured and processed in a way that maintains quality and accuracy.

2. **Specific Standards for Capacitor Images**: Certain standards may dictate how capacitors should be photographed for technical documentation.

D. Use of Digital Images vs. Physical Samples

Both digital images and physical samples have their advantages and disadvantages:

1. **Advantages of Digital Images**: They can be easily shared, edited, and used in online marketing. They also allow for quick updates to product listings.

2. **Disadvantages of Digital Images**: Poorly taken images can misrepresent the product, leading to consumer distrust.

3. **Best Practices for Capturing Capacitor Images**: Use high-quality cameras, proper lighting, and backgrounds to enhance the image quality.

VI. Challenges in Meeting Product Standards

Meeting product standards for capacitor images can be challenging due to:

A. Variability in Capacitor Designs

With numerous capacitor types and designs, creating standardized images can be complex.

B. Technological Advancements in Imaging

Rapid advancements in imaging technology can make it difficult to keep up with best practices and standards.

C. Global Differences in Standards and Regulations

Different countries may have varying standards, complicating international marketing efforts.

D. The Role of Digital Marketing and E-commerce

The rise of digital marketing and e-commerce has increased the demand for high-quality images, putting pressure on manufacturers to meet these standards.

VII. Best Practices for Capturing Capacitor Images

To ensure high-quality capacitor images, consider the following best practices:

A. Equipment and Tools Needed

1. **Cameras and Lenses**: Use a high-resolution camera with macro capabilities for close-up shots.

2. **Lighting and Backgrounds**: Proper lighting is essential to avoid shadows and reflections. Use neutral backgrounds to keep the focus on the capacitor.

B. Techniques for Effective Photography

1. **Angles and Perspectives**: Capture images from multiple angles to provide a comprehensive view of the capacitor.

2. **Focus and Depth of Field**: Use a shallow depth of field to highlight the capacitor while blurring the background.

C. Post-Processing and Editing

1. **Software Options**: Use photo editing software to enhance image quality, adjust colors, and remove imperfections.

2. **Enhancing Image Quality While Maintaining Accuracy**: Ensure that any edits do not misrepresent the product.

VIII. Conclusion

In conclusion, product standards for capacitor pictures are essential for ensuring quality, reliability, and consumer trust. High-quality images not only enhance marketing efforts but also play a crucial role in informing consumers about the products they are purchasing. As technology continues to evolve, staying updated on best practices and standards will be vital for manufacturers and marketers alike. The future of capacitor imaging will likely see further advancements in technology and a continued emphasis on quality and compliance with industry standards.

IX. References

1. International Electrotechnical Commission (IEC) Standards

2. Institute of Electrical and Electronics Engineers (IEEE) Standards

3. Underwriters Laboratories (UL) Certification Guidelines

4. American National Standards Institute (ANSI) Publications

5. European Committee for Electrotechnical Standardization (CENELEC) Guidelines

This comprehensive exploration of product standards for capacitor pictures highlights the importance of quality imaging in the capacitor industry, ensuring that manufacturers can effectively communicate their products' features and benefits to consumers.

What are the Product Standards for Capacitor Pictures?

I. Introduction

Capacitors are essential components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from consumer electronics to industrial machinery. As the demand for capacitors continues to grow, so does the need for stringent product standards in their manufacturing and representation. This article aims to explore the product standards for capacitor pictures, emphasizing their importance in ensuring quality, reliability, and consumer trust.

II. Overview of Capacitors

A. Types of Capacitors

Capacitors come in various types, each designed for specific applications and performance characteristics:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are polarized and often used in power supply circuits.

2. **Ceramic Capacitors**: These non-polarized capacitors are widely used in high-frequency applications due to their stability and low losses.

3. **Film Capacitors**: Made from plastic film, these capacitors are known for their reliability and are commonly used in audio and power applications.

4. **Tantalum Capacitors**: These capacitors offer high capacitance in a small package and are often used in portable electronics.

B. Applications of Capacitors

Capacitors find applications across various industries:

1. **Consumer Electronics**: Used in devices like smartphones, televisions, and computers to stabilize voltage and filter signals.

2. **Industrial Applications**: Employed in machinery for energy storage and power factor correction.

3. **Automotive Industry**: Used in electric vehicles and traditional cars for energy management and signal processing.

4. **Renewable Energy Systems**: Essential in solar inverters and wind turbines for energy storage and management.

III. Importance of Product Standards

Product standards are vital in the capacitor industry for several reasons:

A. Ensuring Quality and Reliability

Standards help manufacturers produce capacitors that meet specific performance criteria, ensuring that they function reliably in their intended applications.

B. Facilitating International Trade

With standardized products, manufacturers can sell their capacitors globally, reducing barriers to trade and fostering competition.

C. Protecting Consumers and Manufacturers

Standards protect consumers by ensuring that products are safe and perform as expected. They also protect manufacturers from liability by providing guidelines for compliance.

D. Enhancing Product Compatibility

Standardized capacitors are more likely to be compatible with various devices, reducing the risk of failure and enhancing user experience.

IV. Key Organizations and Standards

Several organizations play a crucial role in establishing product standards for capacitors:

A. International Electrotechnical Commission (IEC)

The IEC develops international standards for electrical and electronic devices, including capacitors. Specific IEC standards outline performance, safety, and testing requirements for various capacitor types.

B. Institute of Electrical and Electronics Engineers (IEEE)

IEEE standards focus on electrical and electronic engineering practices. Relevant standards for capacitors include guidelines for testing and performance evaluation.

C. Underwriters Laboratories (UL)

UL is known for its safety certification. Capacitors that meet UL standards are tested for safety and performance, providing assurance to consumers and manufacturers.

D. Other Relevant Organizations

1. **American National Standards Institute (ANSI)**: Develops standards for various industries, including electronics.

2. **European Committee for Electrotechnical Standardization (CENELEC)**: Focuses on standardization in the electrical and electronic sectors within Europe.

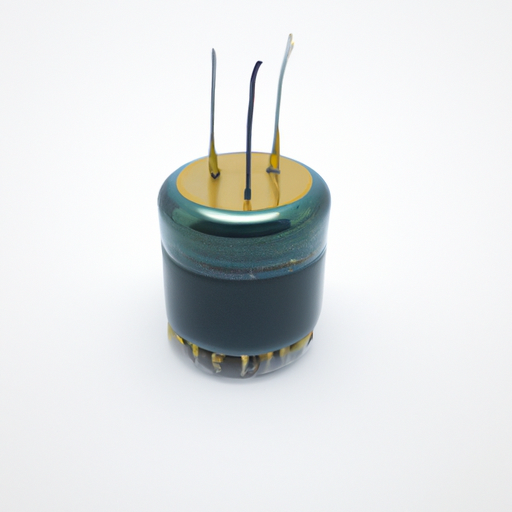

V. Product Standards for Capacitor Pictures

A. Visual Representation Requirements

The visual representation of capacitors is crucial for marketing and technical documentation. Key requirements include:

1. **Clarity and Resolution**: Images must be clear and high-resolution to accurately depict the capacitor's features.

2. **Color Accuracy**: Colors in the images should accurately represent the actual product to avoid misleading consumers.

3. **Size and Dimensions**: Images should include a scale or reference to convey the actual size of the capacitor.

B. Labeling and Markings

Proper labeling is essential for capacitor images:

1. **Manufacturer Information**: Images should include the manufacturer's name and logo for brand recognition.

2. **Electrical Specifications**: Key specifications, such as capacitance value and voltage rating, should be clearly visible.

3. **Safety Warnings and Certifications**: Any relevant safety certifications or warnings should be included in the image.

C. Compliance with Industry Standards

Images of capacitors should comply with industry standards, including:

1. **ISO Standards for Photography**: These standards ensure that images are captured and processed in a way that maintains quality and accuracy.

2. **Specific Standards for Capacitor Images**: Certain standards may dictate how capacitors should be photographed for technical documentation.

D. Use of Digital Images vs. Physical Samples

Both digital images and physical samples have their advantages and disadvantages:

1. **Advantages of Digital Images**: They can be easily shared, edited, and used in online marketing. They also allow for quick updates to product listings.

2. **Disadvantages of Digital Images**: Poorly taken images can misrepresent the product, leading to consumer distrust.

3. **Best Practices for Capturing Capacitor Images**: Use high-quality cameras, proper lighting, and backgrounds to enhance the image quality.

VI. Challenges in Meeting Product Standards

Meeting product standards for capacitor images can be challenging due to:

A. Variability in Capacitor Designs

With numerous capacitor types and designs, creating standardized images can be complex.

B. Technological Advancements in Imaging

Rapid advancements in imaging technology can make it difficult to keep up with best practices and standards.

C. Global Differences in Standards and Regulations

Different countries may have varying standards, complicating international marketing efforts.

D. The Role of Digital Marketing and E-commerce

The rise of digital marketing and e-commerce has increased the demand for high-quality images, putting pressure on manufacturers to meet these standards.

VII. Best Practices for Capturing Capacitor Images

To ensure high-quality capacitor images, consider the following best practices:

A. Equipment and Tools Needed

1. **Cameras and Lenses**: Use a high-resolution camera with macro capabilities for close-up shots.

2. **Lighting and Backgrounds**: Proper lighting is essential to avoid shadows and reflections. Use neutral backgrounds to keep the focus on the capacitor.

B. Techniques for Effective Photography

1. **Angles and Perspectives**: Capture images from multiple angles to provide a comprehensive view of the capacitor.

2. **Focus and Depth of Field**: Use a shallow depth of field to highlight the capacitor while blurring the background.

C. Post-Processing and Editing

1. **Software Options**: Use photo editing software to enhance image quality, adjust colors, and remove imperfections.

2. **Enhancing Image Quality While Maintaining Accuracy**: Ensure that any edits do not misrepresent the product.

VIII. Conclusion

In conclusion, product standards for capacitor pictures are essential for ensuring quality, reliability, and consumer trust. High-quality images not only enhance marketing efforts but also play a crucial role in informing consumers about the products they are purchasing. As technology continues to evolve, staying updated on best practices and standards will be vital for manufacturers and marketers alike. The future of capacitor imaging will likely see further advancements in technology and a continued emphasis on quality and compliance with industry standards.

IX. References

1. International Electrotechnical Commission (IEC) Standards

2. Institute of Electrical and Electronics Engineers (IEEE) Standards

3. Underwriters Laboratories (UL) Certification Guidelines

4. American National Standards Institute (ANSI) Publications

5. European Committee for Electrotechnical Standardization (CENELEC) Guidelines

This comprehensive exploration of product standards for capacitor pictures highlights the importance of quality imaging in the capacitor industry, ensuring that manufacturers can effectively communicate their products' features and benefits to consumers.